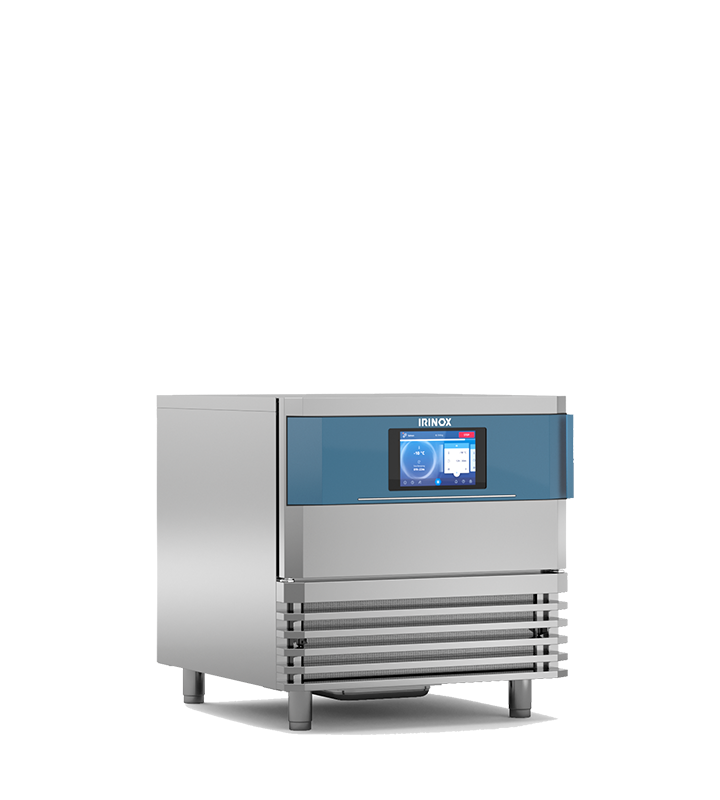

MultiFresh® Next

MultiFresh® Next is the most powerful and efficient blast chiller on the market. IRINOX branded products represent revolutionary technology, guaranteeing unprecedented levels of customization, sustainability, power and innovation.

– 12 functions, 150 cycles

The Entire Range

MultiFresh® Next is available in six models. The dimensions, yield per cycle and tray capacity vary. What does not change is the quality, guaranteed by IRINOX.

Packages and customization

Customise your IRINOX blast chiller to suit your needs, and preserve the freshness of your products for longer.

Configurations

From Essentials to Excellence: choose between two different configurations.

Essential

All the essential features for your kitchen. The base model with all of the most important chilling and freezing functions.

Excellence

For users that want all of the traditional functions of a blast chiller combined with new hot and cold functions designed for the most demanding professionals.

Functions

Choose the configuration and then you can select the perfect cycles and functions for your processes:

Rapid chilling halts the deterioration of foods, stops oxidationand reduces bacterial growth. The IRINOX Blast Chiller brings the core of your products to +3°C from any starting temperature, even boiling hot, maintaining food properties.

Ultra-fast freezing, down to -18°C at the core, guarantees formation of microcrystals that do not compromise the structure of foods, maintaining flavour and aroma profiles, even after defrosting.

For non-stop chilling and freezing of unlimited quantities of foodstuffs prepared an placed into the blast chiller in succession. The IRINOX Blast Chiller allows you to catalogue each product with personalised time, icon, name and colour and set end-of-cycle notifications for each tray.

This transforms the blast chiller into temporary additional storage at the desired temperature.

Keep products at up to +65°C, allowing you to serve them at their optimal temperature, ready to enjoy.

Set the temperature and time when you want your foods to be ready for use, slowing the process of bacterial growth.

Bring foods up from -18°C or +3°C to a maximum of +65°C at a desired time, restoring their properties, maintaining moisture levels and avoiding oxidation.

Cook meat or fish at low temperatures, alsoovernight, switching automatically to chillingor freezing as soon as cooking is complete.

Set the ideal temperature for melting chocolate at +45°C, maintaining moisture levels and the correct temperature.

MultiFresh® pasteurizes and chills (+3°C) or pasteurizes and freezes (-18°C) products, reducing bacterial contamination and increasing shelf life.

Carry out proofing without excessive temperature changes, controlling humidity levels in the chamber and setting a time for your products to be perfectly proofed, ready to transfer to the oven or store at +3°C or -18°C. The table on the right details the three different proofing functions.

Performance

Choose the configuration based on your needs

Standard

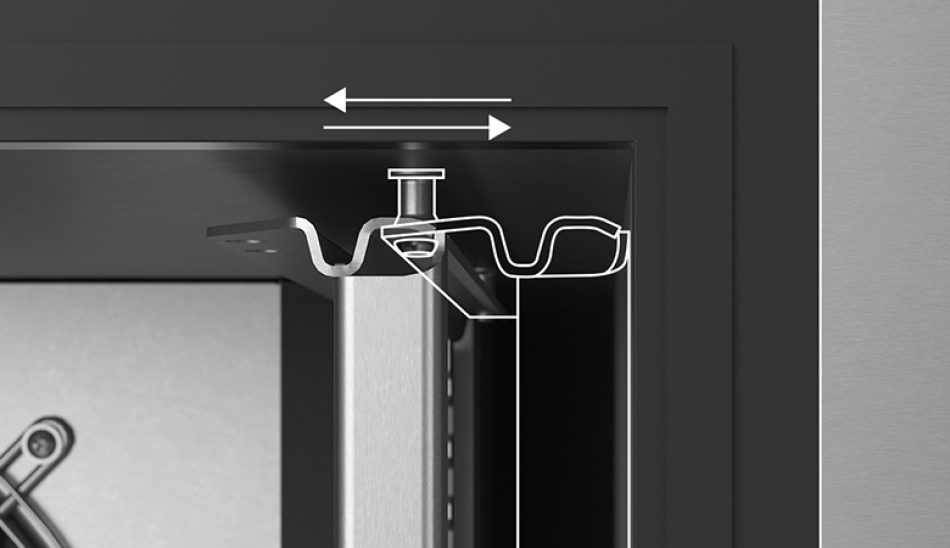

Guarantees excellent results and quality for chilling and freezing. The temperature in the chamber is always uniform thanks to fixed-speed fans specially designed for low temperatures. This is a climate class 4 solution (30°C ambient temperature).

Not available for SL, ML and LL models.Turbo

Top-of-the-range solution for professionals that need high performance, power and speed: the specifications on this product allow an increase of up to 30 in chilling and freezing capacity.

The new blast chiller, complete with Turbo package, guarantees excellent results over 40°C ambient temperature, making it climate class 5.Ecosilent

The Eco Silent package guarantees efficient performance combined with extremely low noise emissions. The perfect option for companies subject to noise limits or that pay particular attention to quality of the working environment.

Turbosilent

Turbo Silent package combines the excellent performance of the Turbo version with the low noise levels of the Silent version. The result is a model with 30% greater chilling and freezing output compared to standard performance yet silent despite the extrapower, thanks to the soundproofing kit.

Not available for S and SL models.

Design & Technology

Technology that makes life easier

Why Choose MultiFresh® Next

Choose a reliable technology that facilitates and improves your work.

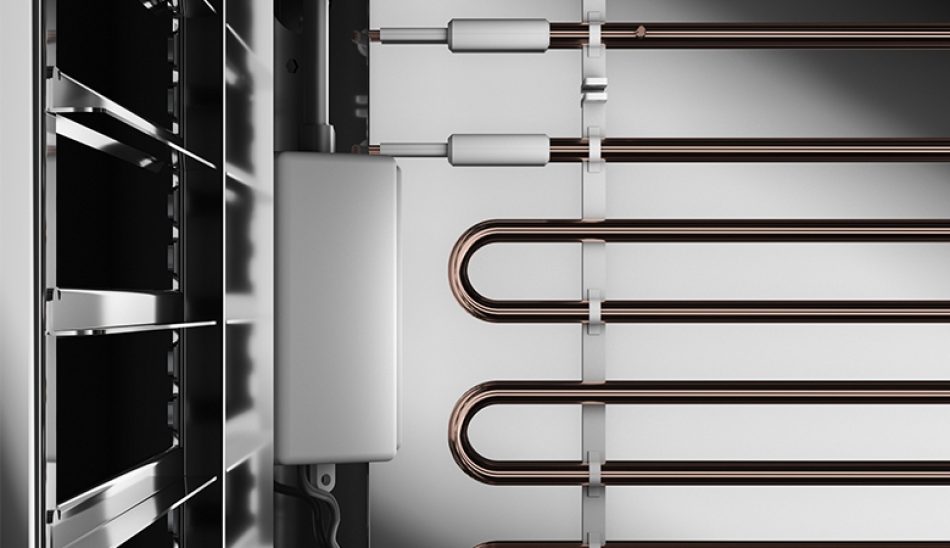

- 01/ Performance

The best for those who need high performance, power and speed of cooling and freezing.

- 02/ Efficient

Maximum energy efficiency. Both in chilling and freezing, the IRINOX blast chiller consumes significantly less energy, allowing you to make unparalleled energy savings.

- 03/ Sustainable

IRINOX blast chillers use R290 propane, an environmentally sustainable natural gas that reduces both environmental impact and costs.

- 04/ Customizable

With MultiFresh® Next by IRINOX you have all the possible functions available to customize your blast chiller. You can configure it according to your needs and create equipment tailored to your kitchen or laboratory.

— Discover how to enhance your recipes with the IRINOX system

— A personal hub full of extra features dedicated to our customers