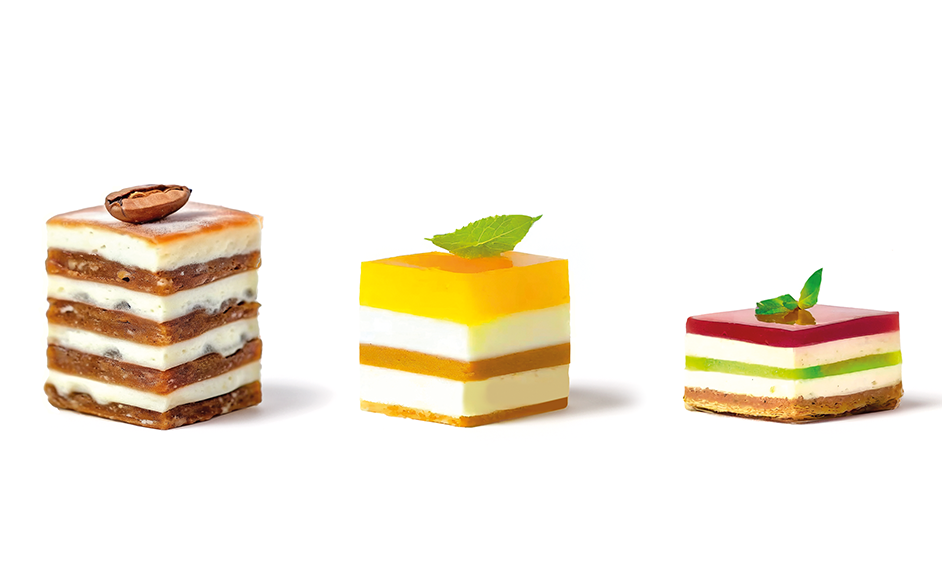

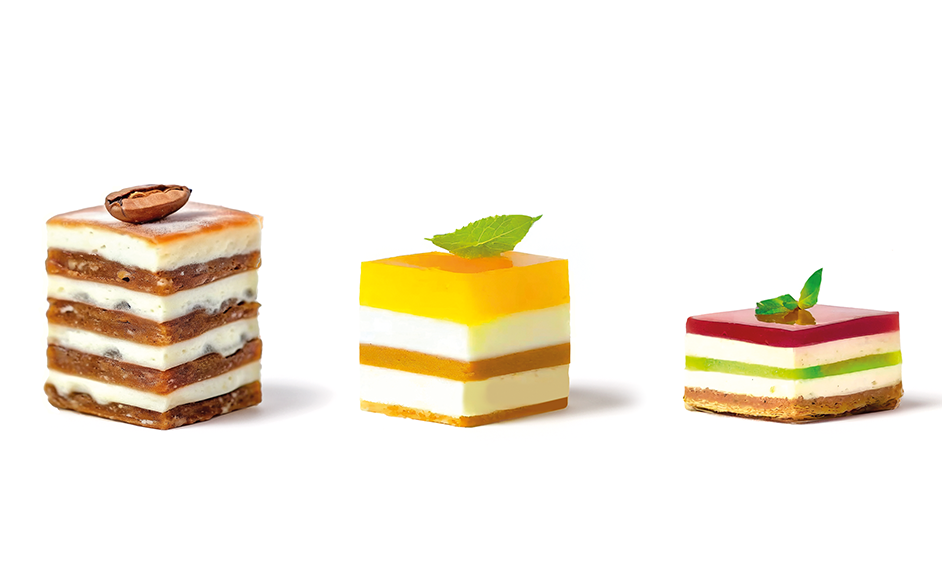

Confectionery

Enhance the quality of your creations and optimize production costs

Always at your side for excellent management of your production workspace.

In the confectionery industry, production optimization is crucial to meet the increasing demands of customers. IRINOX equipment is designed to meet the needs of both small workshops and large-scale confectionery production, combining innovation and practicality. Our solutions make it possible to offer fresh, high-quality products, minimizing waste and coping with production peaks effortlessly.

IRINOX’ practicality in your life

— A quality choice to revolutionize your confectionery workspace.

Uncompromising quality

Invest in IRINOX to raise the quality level of your creations.

In the confectionery industry, production optimization is crucial to meet the increasing demands of customers. IRINOX equipment allows you to preserve the quality of your creations, while ensuring maximum food safety and optimizing workflows. Our blast chillers and shock freezers quickly chill or freeze desserts, pastries, creams and freshly baked products, preserving their freshness and consistency. In this way, you can prepare products in advanced, in less time, reduce waste and manage production easily.

Increase shelf life

Retain freshness

Preserve the quality, aroma and flavour of your creations for an extended period of time.

Extending the food shelf life is essential to reduce waste, preserve its organoleptic characteristics and optimize stock management. IRINOX cold chain helps keep products fresher and more appealing, extending their shelf life by up to 3 times longer*.

*Guaranteed increase with a proper use of the cold chain, which includes IRINOX blast chiller and holding cabinet.

Preserve the original weight

Reduce weight loss

Ensure that every cake is perfect, in every detail.

One of the most common challenges of the confectionery industry is the product’s loss of weight, due to the moisture-loss while they chill down to room temperature. IRINOX blast chillers and shock freezers offer an effective solution to chill or freeze your creations quickly, including cakes, pastries and croissants, and ensure they retain their original weight and quality.

Uncompromising quality

Invest in IRINOX to raise the quality level of your creations.

In the confectionery industry, production optimization is crucial to meet the increasing demands of customers. IRINOX equipment allows you to preserve the quality of your creations, while ensuring maximum food safety and optimizing workflows. Our blast chillers and shock freezers quickly chill or freeze desserts, pastries, creams and freshly baked products, preserving their freshness and consistency. In this way, you can prepare products in advanced, in less time, reduce waste and manage production easily.

Retain freshness

Preserve the quality, aroma and flavour of your creations for an extended period of time.

Extending the food shelf life is essential to reduce waste, preserve its organoleptic characteristics and optimize stock management. IRINOX cold chain helps keep products fresher and more appealing, extending their shelf life by up to 3 times longer*.

*Guaranteed increase with a proper use of the cold chain, which includes IRINOX blast chiller and holding cabinet.

Reduce weight loss

Ensure that every cake is perfect, in every detail.

One of the most common challenges of the confectionery industry is the product’s loss of weight, due to the moisture-loss while they chill down to room temperature. IRINOX blast chillers and shock freezers offer an effective solution to chill or freeze your creations quickly, including cakes, pastries and croissants, and ensure they retain their original weight and quality.

Perfect for your sector

MultiFresh® Next

MultiFresh® Next is the most powerful and efficient blast chiller on the market. IRINOX-branded products represent a revolutionary technology, delivering unprecedented levels of customization, sustainability, power, and innovation.

Casa Manfredi

EasyFresh® Next

Quick blast chiller/shock freezer. In the kitchen, EasyFresh® Next is your indispensable ally to preserve your food’s freshness, quality and safety. With its fast chilling and freezing processes, it preserves the food’s organoleptic properties, optimizes work processes and reduces waste, ensuring perfect dishes on every occasion.

CP Next

The new green generation of professional preservation

For over 20 years, IRINOX has been a trusted name in preservation for the pastry and gelato industry. Today, our preservation module evolves: more sustainable, more compact, with the same reliable performance.

Bar Lucia

Need more information?

Write to us! We are at your disposal for any information.