MultiFresh® MyA

IRINOX roll-in blast chiller and shock freezer is the ideal ally for high-volume production laboratories, designed to guarantee excellent performance in dynamic and ever-changing environments. With its advanced technology, MultiFresh® MyA offers unparalleled reliability, optimizing operational efficiency and perfecting every step of the production process.

– 10 functions, over 90 customizable cycles

The entire range

Available in different models, MultiFresh® MyA offers solutions customized to your production needs, ensuring excellence, efficiency and versatility in every context. You can choose between two configurations and type of refrigerant gas used: R452A, R404A (on request) or natural refrigerant gas CO2.

Bundles and customization

Customize MultiFresh® MyA according to your production needs for maximum efficiency and performance.

Configurations

Choose the configuration that best suits your production needs.

Plus

Maximum versatility in a single solution. In addition to Standard cycles, it offers advanced features such as defrosting, proofing, low-temperature cooking, warm holding, regenerating, pasteurization and chocolate.

Standard

Essential and efficient: includes chilling, freezing and non-stop cycles. Ideal for those looking for reliable performance in key cold chain processes.

Features

Based on the configuration you opt for, you can choose between several functions designed to optimize your production needs.

Rapid chilling halts the deterioration of foods, stops oxidation, and reduces bacterial growth. The IRINOX Blast Chiller brings the core of your products to 37 °F from any starting temperature, even boiling hot, maintaining food properties.

Shock freezing, down to 0 °F at the core, guarantees formation of microcrystals that do not compromise the structure of foods, maintaining flavor and aroma profiles, even after defrosting.

For non-stop chilling and freezing of unlimited quantities of foodstuffs prepared and placed into the blast chiller in succession. The IRINOX Blast Chiller allows you to catalogue each product with personalised time, icon, name, and color, and set end-of-cycle notifications for each tray.

Set the temperature and time when you want your foods to be ready for use, slowing the process of bacterial growth.

Carry out proofing without excessive temperature changes, controlling humidity levels in the chamber and setting a time for your products to be perfectly proofed, ready to transfer to the oven or store at +37 °F or 0 °F.

Cook meat or fish at low temperatures, also overnight, switching automatically to chilling or freezing as soon as cooking is complete.

MultiFresh® Mya regenerates all types of food, preserving their natural moisture and preventing oxidation. You can set the serving time and bring your food from +3°C to the ideal consumption temperature.

MultiFresh® Mya keeps food at a constant temperature, both positive and negative, preserving organoleptic properties and ensuring optimal storage.

MultiFresh® pasteurizes and chills (+37 °F) or pasteurizes and freezes (0 °F) products, reducing bacterial contamination and increasing shelf life.

To melt chocolate gently, keeping humidity under control and ensuring the ideal temperature for perfect melting.

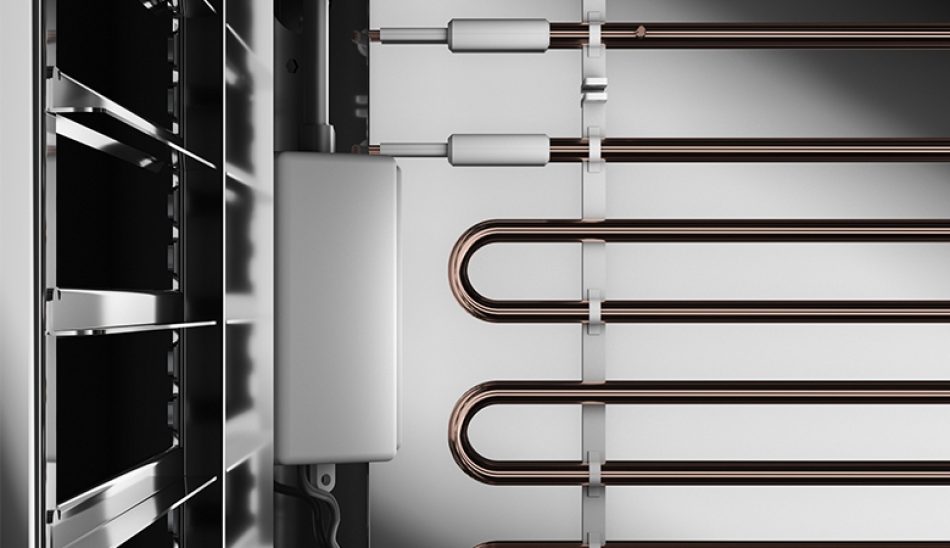

Design & Technology

Technology that makes life easier

Why choose MultiFresh® MyA

Choose a reliable technology that optimizes your work, guaranteeing high performance and flawless results even with large production volumes.

- 01/ Efficient

MultiFresh® Mya allows large volumes of product to be quickly chilled and frozen, reducing waiting times between production steps. This ensures greater business continuity and reduced processing times, improving the overall efficiency of the production kitchen. Being so versatile, MultiFresh® Mya also offers controlled defrosting, regenerating, proofing, low-temperature baking and many other options, adapting perfectly to different professional needs.

- 02/ User-friendly

MultiFresh® Mya stands out for its user-friendly touch-screen interface, making every operation simple and straightforward. You can choose from many preset cycles, designed to preserve the organoleptic properties of each food, and easily adapt them to your needs. With the option of editing the parameters of each cycle, you can achieve the ideal treatment for each product, guaranteeing optimal results.

- 03/ Connected

The FreshCloud® platform offers an advanced remote monitoring and control system, allowing you to manage operational cycles and consult HACCP reports directly from connected devices. The entire Multifresh® Mya process can be monitored in real time, ensuring efficiency and regulatory compliance.

— A personal hub full of extra features dedicated to our customers

— A personal hub full of extra features dedicated to our customers